Low-carbon electricity: one of the textile industry’s biggest challenges? Yes, but…

Article published on

Are you surprised by the title and the photo of the article? It’s normal. The link between a t-shirt and a wind turbine producing electricity is difficult to make at first sight.

Yet electricity (its production & its use) is a major issue, for Picture, for the textile industry, and for the whole world in the fight against climate change.

1. The production of electricity (via coal, gas and oil power plants) is one of the first causes of greenhouse gas emissions (GHG, including CO2) in the world. Coal, gas and oil account for about 65% of the electricity produced in the world.

2. Low-carbon alternatives are those that emit very little CO2 (life cycle analysis): nuclear, hydroelectricity, wind, solar, biomass, geothermal, etc. Together, these alternatives represent about 35% of the electricity produced in the world.

3. Electricity is everywhere. Everything around us has been manufactured in some way with machines that need electricity to function. Even our electronic devices, after being made by machines, still need electricity to work.

Of course, electricity is produced because there is a demand; there’s an economic model that is very energy intensive. In this article, we will try to link the issues of energy transition to the imperative of sobriety. As economic anthropologist Jason Hickel says in this article, “Using less energy makes decarbonization easier“.

This concludes the intro.

Now, let’s turn to our story about the t-shirt and the wind turbine.

What connection can we make between the two?

It’s quite simple: without electricity, the t-shirt could not be made. Electricity-hungry machines (spinning, weaving, dyeing, etc.) are omnipresent in the manufacturing of clothing.

In other words, although your material is potentially “responsible” at the base of your supply chain (in the fiber state for organic cotton or in the pellet state for recycled polyester, for example), it’s still a long and energy-intensive road to a wearable finished product.

Of course, there are still men and women behind the processes – they undeniably had the know-how. Our ancestors did not wait for the invention of electricity to dress themselves! Historically, craftsmanship has always allowed us to make clothes.

Then the industrial revolution (from 1850) came along. The invention of electricity and the massive growth of fossil fuels (oil, coal, gas) have, among others, shaped the world we know today. We are not denying the positive progress in areas such as health and education that this growth drove. The textile industry (like all other industries) then became largely industrialized and the race for “more and more” started gently, before really intensifying in the 1990s.

In the rest of this article, you may read things that brands don’t usually talk about. But hey, we have to move on, question ourselves and improve!

And above all, it’s not only about Picture. The questions are bigger: what kind of society do we want? What is the place of the textile sector in the ecological transition? What is the role of companies? What are the key actions to fight against climate change and stop the collapse of biodiversity?

1. Textile industry: Where are greenhouse gas (GHG) emissions located?

Firstly, in order not to add length to an already lengthy article, we have decided to refocus the impacts of textiles around the climate issue. This is reductive as other planetary limits exist, but we assume this refocusing for this article.

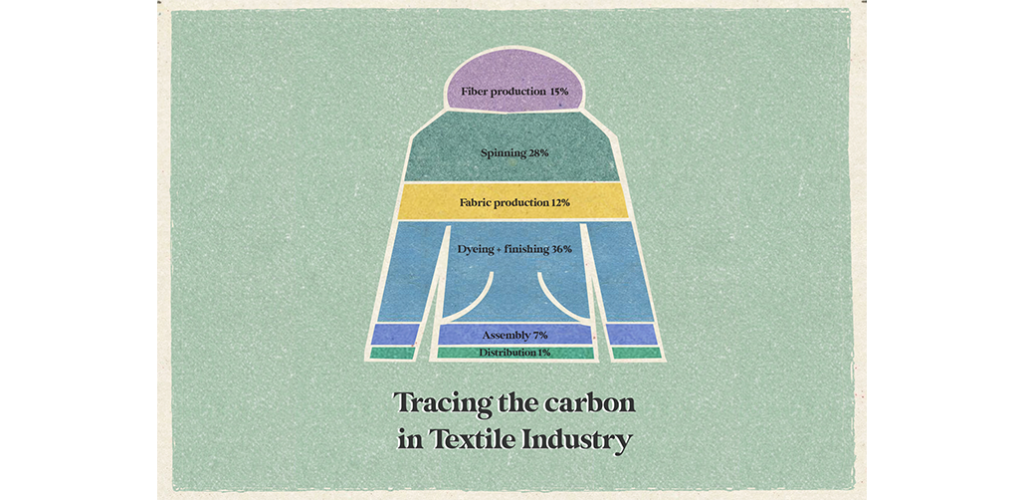

According to the study “The Environmental Impact of the Global Apparel and Footwear Industries” published by the firm Quantis in 2018, the average carbon impact of a textile product in the world is distributed as follows:

83% of the carbon impact of a textile product is therefore located, on average, in the stages of: spinning, knitting/weaving, dyeing, special treatments and assembly. In other words: the manufacture of clothing.

- Cotton,

- Synthetics (ex.: polyester, nylon, etc.),

- Cellulose-based materials (viscose, lyocell, etc.),

- Other natural/animal materials (linen, hemp, wool, leather, etc.).

Note: for transportation, this refers to the transportation of finished products from the assembly plants to the stores. The study used figures from another report (The Environmental Potential of Textile, 2014) estimating that 8% of global textile transport was by air, and 92% by road/sea. The study states that the negative impact of transportation would be much greater if brands did more shipping by air. Let’s keep on not doing it then!

To be complete, we should also add the emissions linked to the use of the products (washing, ironing, etc.) and linked to the end of life (recycling, incineration, etc.), but this would not change the order of magnitude.

2. What causes emissions?

The main cause, common to all manufacturing stages, is the use of electricity by the machines. The study points out that:

– “Heavy reliance on coal and natural gas to generate electricity and heat (especially in Asia) are largely responsible for emissions.” (pg 21)

– “The different modes of electricity generation directly influence the environmental (including climate) outcomes of textile processes. “ (pg 62)

Admittedly, there is some transportation between the manufacturing stages. This will cause emissions, but it is not significant.

The electricity mix of the production countries is therefore a key factor.

Mixes that are too carbon intensive (majority of coal, gas, & oil) will lead to CO2 emissions. Conversely, if a majority of low-carbon electricity is identified (nuclear, hydro, wind, solar, biomass, geothermal, etc.) then the good news is that the CO2 emissions associated with the manufacture of the product will be very low.

Bad news: It’s hard to find a country with low-carbon energy mix AND that same country with a textile production sector… We will see later on what the other levers for improvement are. Here is how the origin of electricity, a subject largely hidden in the textile industry suddenly becomes one of the first priorities to reduce CO2 emissions and develop low carbon products!

Here is how the origin of electricity, a subject largely hidden in the textile industry suddenly becomes one of the first priorities to reduce CO2 emissions and develop low carbon products!

3. Materials and transport are therefore secondary

You were probably surprised to see the small percentages that these 2 steps represent. However, they are the ones that come directly to mind because:

1. Brands often emphasize materials (organic, recycled, etc.).

2. Transportation is a “naturally” counter-intuitive subject because we tend to associate a lot of CO2 emissions with a product that comes from far away…

We are not saying that these steps are not important. They are. However, when it comes to carbon emissions, they are clearly less important relative to the issue of energy/electricity use, which amounts to 83% of the textile industry’s overall impact.

So how do we explain this discrepancy between reality, communication and counter-intuition?

Hard to say. There has probably been a lack of awareness of the impacts within the industry, even if the gap is now being closed.

Instead, here are the main sustainability themes that have driven textile professionals for so many years: Materials, sustainability/repair, circular economy, recycling, polybags, harmful chemicals and transportation. These topics are all important, they have all progressed well, improvements are real, brands are talking about it, it’s normal.

But there are obviously 2 major absences: energy transition and sobriety.

Even the French brands (which have the advantage of benefiting from the very low-carbon French electricity mix) and even those that manufacture in Portugal (also a low-carbon mix) hardly talk about it!

From a marketing point of view, it is clear that we are not on the sexiest subject… Also, there is probably a reluctance of brands to talk about subjects on which they are not a leader.

Finally, the carbon slider (climate change) is not necessarily the main focus of all brands. There may be other commitments (biodiversity, relocation, circular economy, social aspect, etc.) that lead to other debates and actions.

4. Just an electricity problem?

As we mentioned at the beginning of this article, if electricity is produced, if textile machines are running and CO2 emissions are caused, it is not for nothing. It’s because there is a demand for (over)production from the brands, which globally encourage to (over)consume.

Below, some statistics that cannot be ignored.

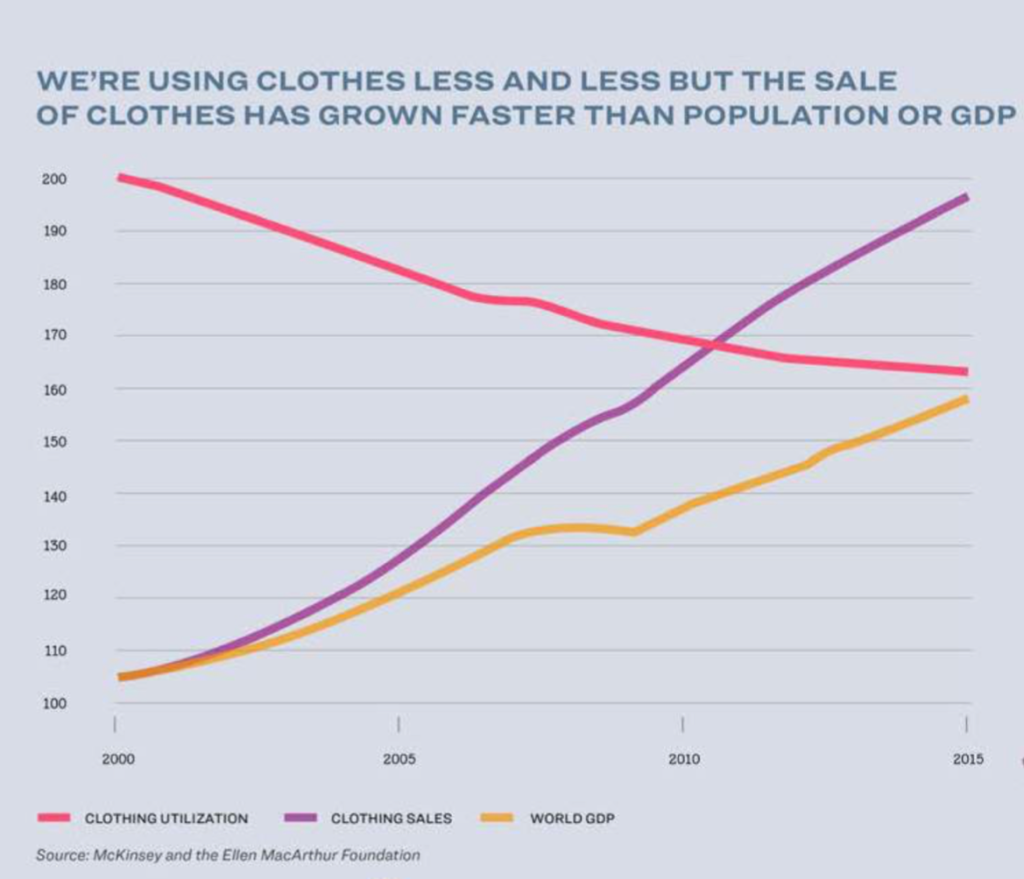

In purple, the evolution of the volume of clothing sales in the world between 2000 and 2015: +100%.

In red, over the same period, the use we make of clothes: -20%. As we wear them more and more, but there are no more days in the week to wear them than before… we wear them less and less.

In yellow, the evolution of the world GDP over the same period: +50%.

But there are more of us on Earth? So, we have to dress more and more people? Well… we were 6 billion people in 2000, then 7.3 billion in 2015: +21%

Why is the volume of textile sales doing its little +100% while the population has increased “only” by +21% over the same period? And here we won’t even talk about inequalities…

BRIEF.

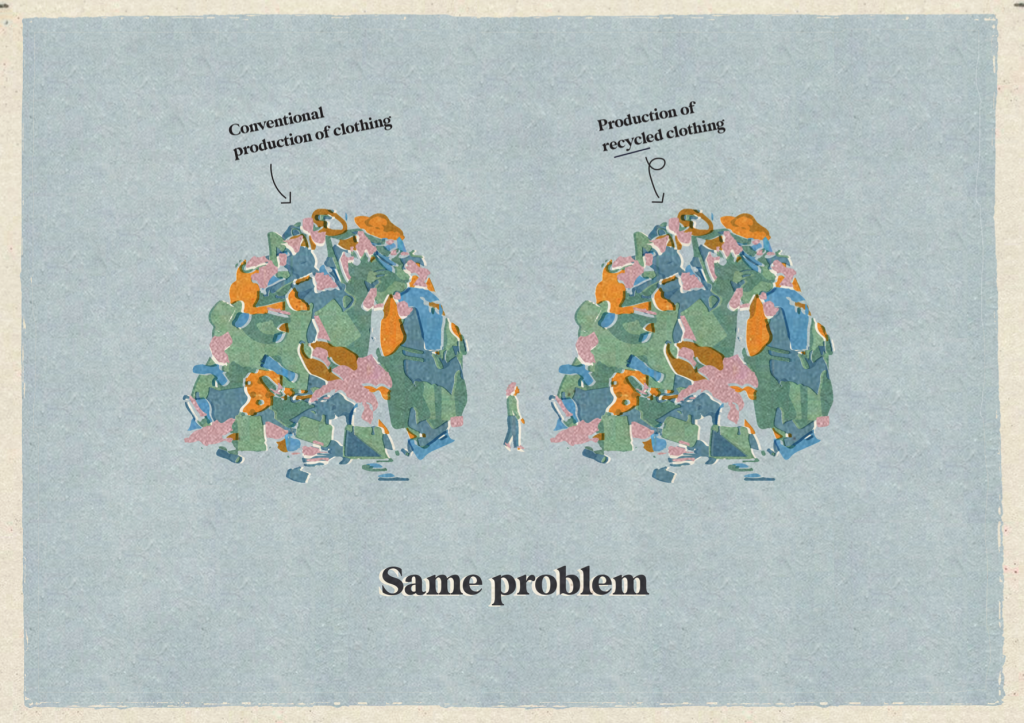

So, we do have a volume of production problem. But at the same time, we see many improvements, right? Recycled materials, reusable packaging, certifications, collection points, second hand, modern machines consuming less energy, etc.? That’s true, but the mentioned improvements don’t say anything about the total consumption. Multiple rebound effects are always possible. When we are more efficient, we generally produce more.

Climate, biodiversity and degraded ecosystems don’t care about a relative reduction of impact per product, per collection or per euro of turnover. What is crucial is to reduce the absolute value.

However, the dynamics of the textile industry are the exact opposite. Improvements “at the margin” are legion and maintain business as usual, with notably the worst practices of fast fashion:

- Low prices

- Renewal of the collection between 5 and 20 times a year

- Multiple incentives to consume (i.e. sales, Black Friday, etc.)

If this dynamic is not stopped, the textile industry’s emissions will increase by 49% by 2030 to reach 5 billion TCO2e, which is equivalent to the annual emissions of the USA (Quantis, 2021.) A quick reminder: global greenhouse gas emissions must be reduced by -43% by 2030 to keep the temperature rise below +1.5°C.

5. So what do we do?

We need to do things differently. This is where the notion of sobriety comes in: a modification of our organization as a society in order to reduce our energy needs. These transformations have the potential to reduce our global emissions by 40 to 70% (Source: IPCC, AR6 WGIII).

Once again, “using less energy makes decarbonization easier”. This unstoppable little sentence is signed by the economic anthropologist Jason Hickel, author of numerous works on degrowth and inequality.

Finally, fossil fuels are in finite quantity in the ground. For oil, at constant production and according to known reserves, there would still be enough for about fifty years. The more we extract, the more we will miss our climate objectives. The more we depend on it, the more we will have to wean ourselves off it. Great! As oil expert Mathieu Auzanneau would say, “Energy abundance was an adolescent crisis, now we can collapse or go into adulthood”.

To summarize, we must therefore activate the change in our social model and initiate the exit from fossil fuels, because the two go hand in hand. To return to our original example, solar panels will be able to satisfy the energy needs of the factory if it does not increase its production volume every year.

Imagine a textile factory in Taiwan installing solar panels on its roof. These will be useful to move away from coal and gas and will satisfy part of the factory’s energy needs… provided that the factory in question does not increase its production volume every year. Sobriety and energy transition are always linked.

But a question arises: what does this factory manufacture? Low-cost clothes for fast-fashion or work clothes for thermal renovation sites? Can the social utility of the clothes manufactured justify the increase in volume? More globally, what role do companies have in the transition? For some, what is their capacity to replace more polluting alternatives, to get involved in changing the laws? Also, it is often said that companies must reduce their emissions, which is true. But then, how can we consider those who, by increasing their emissions, largely reduce those of others? For example, it would be a pity if a company selling heat pumps reduced its emissions (and therefore its activity) when it plays a major role in replacing oil-fired boilers.

The problem with the textile sector is that there is almost no such replacement model. Why not? Because the most ecological clothing is the one we already own. This sentence may be a bit of a cliché, but it is very true, and is decisive for the future of this industry.

Let’s not beat around the bush, sobriety in textiles consists in producing less and consuming less. This won’t happen willy-nilly; this must be organized, planned and politicized. Within this general framework, some companies will be very affected, and others will be able to continue to manufacture and sell durable, quality clothing.

Moreover, we have seen that a reduction in energy needs facilitates decarbonization. The latter is possible by activating several levers, including collaboration between brands / competitors.

There is also another way of looking at it. Our activity mechanically increases the energy needs of certain countries, which makes their transition to low-carbon energy more complex and costly. So, we have a direct responsibility. Investing financially, helping them and collaborating with other brands in the industry is a fair return and will benefit everyone: emissions are local, but climate impacts are global.

6. Our angles of attack: collaboration and lobbying

- European Outdoor Group: decarbonization group

Together with several outdoor brands, we are working to accelerate the removal of coal, oil and gas from our supply chains. This work is done in 3 steps:

- Identification of some partners we have in common (spinners, weavers, dyers) especially in Taiwan.

- Financing of an energy audit at the identified partners in order to understand what actions to take to get out of fuel oil, coal and gas. Is it better to tackle that ugly oil boiler? Install solar panels on the roof?

- Collective decision to finance the key actions identified. Each brand invests up to its share of the production volume of the targeted plant.

Work started in 2022. Financing of the first actions in 2023.

One thing is certain: without collaboration with brands bigger than us, not much will happen. We represent too little volume (and business) with our target partners compared to the changes we would like to drive with them! So to date, we have little influence.

Also, a solar roof installation is already in place at our spinning/knitting mill Ucak, located in Turkey, dealing with a large part of our streetwear collection. The solar panels allow us to satisfy about 35% of our electricity needs and to “move away” from the more carbon-intensive Turkish national mix.

- Vietnam Solar Panel Project

In collaboration with BayWa R.e., a solar energy provider, we propose to our Vietnamese partners (tier 1 – garment manufacturing) to install solar panels on their roof. More precisely, their roof is rented to the supplier, and the solar panels are connected to the local grid. The solar energy will allow to satisfy 15% to 30% of the electricity needs and another key benefit is to reduce the costs.

- Energy relocation

It is a question of relocating certain productions to countries where electricity is low (or even very low) in carbon. France, Portugal, Spain, Vietnam (to a lesser extent), Latin America, South America, some Eastern European countries are examples where low-carbon textile production exists. Click here to better understand why relocating to France is not so simple in our case, especially because our distribution model (which is not completely fixed) adds an intermediary between Picture and you: the store.

To date, for the majority of our production, we have not really activated this option of relocation. Why? Because there would be the consequence of “abandonment” to our historical relations (2009) with Turkey and Taiwan. The volumes realized with them are important. In short, we admit that these are decisions that are far from easy to make. We are thinking more about energy relocation for other products and accessories that represent less volume. This is what we are already doing for socks (Portugal) and neck warmers (France/Italy).

- Investment with En Mode Climat

Since the beginning of 2022, Picture is an active member of En Mode Climat. Through this collective, we realize that the textile sector will only be able to reduce its impact on the climate and biodiversity if the law forces all companies to change their practices. The progression of committed brands does not slow down the acceleration of fast fashion, or even ultra-fast fashion.

En Mode Climat therefore exists to turn the tables and use the regulatory framework to make changes. Penalize the worst practices and encourage the virtuous ones. We cannot expect every company in the textile sector to make its transformation if the laws do not say so. So, with the 600+ members of the collective, we are using our power of influence to push for regulations that will force all actors in our sector, including us, to do better.

At Picture, we are particularly active in bringing together new members.

Click here for more information on our investment with En Mode Climat

7. Other actions of sobriety and energy transition.

- Our lifetime reparability guarantee and all our advice to make your products last.

- Our rental service, to change production and consumption practices, as well as the dedicated article where we compare purchase and rental models.

- Our zero Black Friday policy.

- Reconditioned products we sell on Everide

- Our presence in low-carbon countries for the production of electricity like France (neck warmers) or Portugal (socks).

THE END

You made it to the end! Congrats! Thanks for reading 🙂