If you said the first time you saw Picture was on the Basque coast and what you saw was a wetsuit, we would have a hard time believing and question:

« Weren’t you on the slopes, rather than in the ocean? »

This year 2018 is our 10th anniversary. Yet, we are only at our 2nd surfing wetsuit collection! There is one main reason why we waiting so long before taking the plunge: to bring an environmentally sound, innovative product to replace the traditional, polluting Neoprene.

As a matter of fact, neoprene is the reference and material exclusively used in the industry since the first surfing wetsuits.

Belonging to the elastomers family, along with rubber, it is also one of the most polluting material on earth: petroleum extraction and its chemical transformation into a neoprene foam are 2 energy intensive stages.

Until the early 2000’s, not one brand acknowledged the issue. Same case for materials suppliers. Slowly, a broad awareness of climate change led the textile industry to acknowledge the need and demand for responsible consumption behaviours and environmentally sound methods.

Thereupon, we saw the democratization of the use of organic and recycled materials merging and now, all stakeholders take on the challenge to work towards alternative solutions.

This worked for the wetsuit as well. At the time, several players (brands + suppliers) tried to find a way to replace neoprene. Looking at the automotive industry, which uses natural rubber to make tires, sourcing bio-based material became a viable alternative to petroleum.

Despite this, there are 2 reasons why only a few brands chose to pursue the search for an ecofriendly material:

– Surfers generally adopt a brand and product that suit their needs perfectly. A surfer will not walk away from a winner product (comfort, fit, feeling, no chafing).

– The cost of raw material is high, due to the small production volume across the industry.

A transition towards a responsible industrial production is only beginning and still represents a small proportion of the global offer from surfwear brands. Thus, we are proud to be pioneers of the movement.

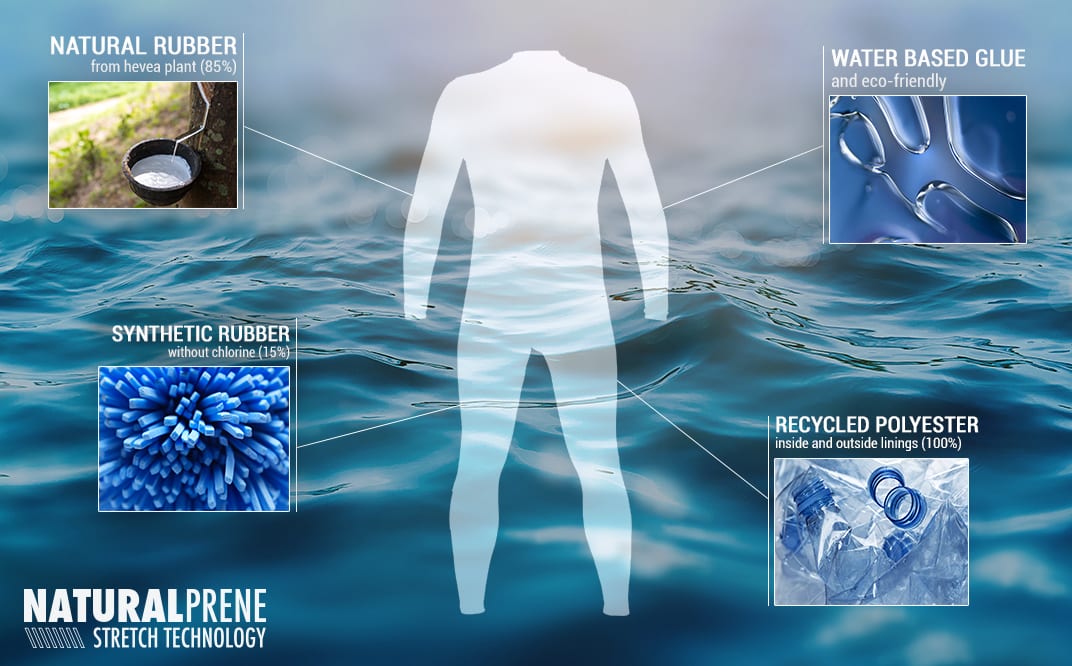

Our wetsuits result from the assembly of 3 eco-friendly components:

1/ NaturalPrene

NaturalPrene replaces neoprene and it is made of 85% natural rubber from the hevea tree. Rubber latex is harvested directly on the trunk of the tree. To extract the latex, an oblique incision is made in the rubber tree’s bark. Thus, this raw material is 100% natural and comes from the trees.

In terms of carbon footprint, the impact is reduced significantly, when compared to petroleum extraction process which is used in a traditional neoprene production.

The hevea plantation we are sourcing from is located in South America and certified FSC® (Forest Stewardship Council) and by the Rainforest Alliance.

Our business partner Sheico transforms the latex into a foam, which takes the shape of neoprene while maintaining its performance properties: durability and stretch.

The remaining 15% is synthetic rubber from a petroleum free source.

2/ Aqua-A™ solvent free glue

A solvent free Aqua-A™ glue is used on both sides of the foam to bind the layers of a recycled polyester fabric. The solvent component generally used in glue is an allergenic, hazardous and volatile substance. Imagine a board shaper working with a mask: He uses this protection against these same solvents.

3/ Recycled polyester lining and shell fabrics

Both made of recycled polyester fabrics from recycled plastic bottles, the lining is warm and quick drying, while the shell fabric is water repellent. One wetsuit recycles approximately 45 plastic bottles.

Today, NaturalPrene is the most responsible material but also the most expensive and it ultimately drives the higher price at retail.

Since Picture was created, our desire was to offer eco-designed products keeping up in prices with the competition’s offering no eco friendly option.

This statement has a direct impact on our margins (and indirectly, on our investment capacity, in marketing for instance) but we are glad to see a cultural change and more and more stakeholders following the lead and choosing responsible materials (organic cotton, recycled polyester). Through economies of scale, purchase prices are getting lower.

We want to keep this commitment working on wetsuits, but we know that NaturalPrene, as eco friendly as it is, is still a very expensive product.

With the intention to offer less expensive products, we developed wetsuits with Limestone, a product we named after its source: the limestone, a material containing no petroleum.

We acknowledge the high energy requirements of the limestone’s chemical transformation process into a neoprene foam. This is why we are already looking to develop our future collections with less limestone and eventually replace it with a new material (which will probably be made of rubber from recycled tires).

In fact, this trade-off NaturalPrene/Limestone is similar to what we are doing with ski jackets, using traditional polyester/recycled polyester in order to reach a reasonable retail price.

Through our research and development process and alternative offers to neoprene, we hope to inspire a cultural change and gain as many followers as possible towards a responsible consumption.

We recognize that bringing environmental innovation without ensuring performance and comfort is pointless. Consequently, our wetsuits offer actual performance properties and features detailed with each product specifications.

This summer, we will be holding our first tour on the Basque coast, in partnership with our local dealers: come and meet with us and test our wetsuits. Tour dates will be announced shortly!

Check out our wetsuits collection: here!