In October 2018, we traveled to Taiwan to retrace every step in the snow jacket manufacturing process, from recycling plastic bottles to making the finished product.

Episode #3: Weaving fabric from spools of thread

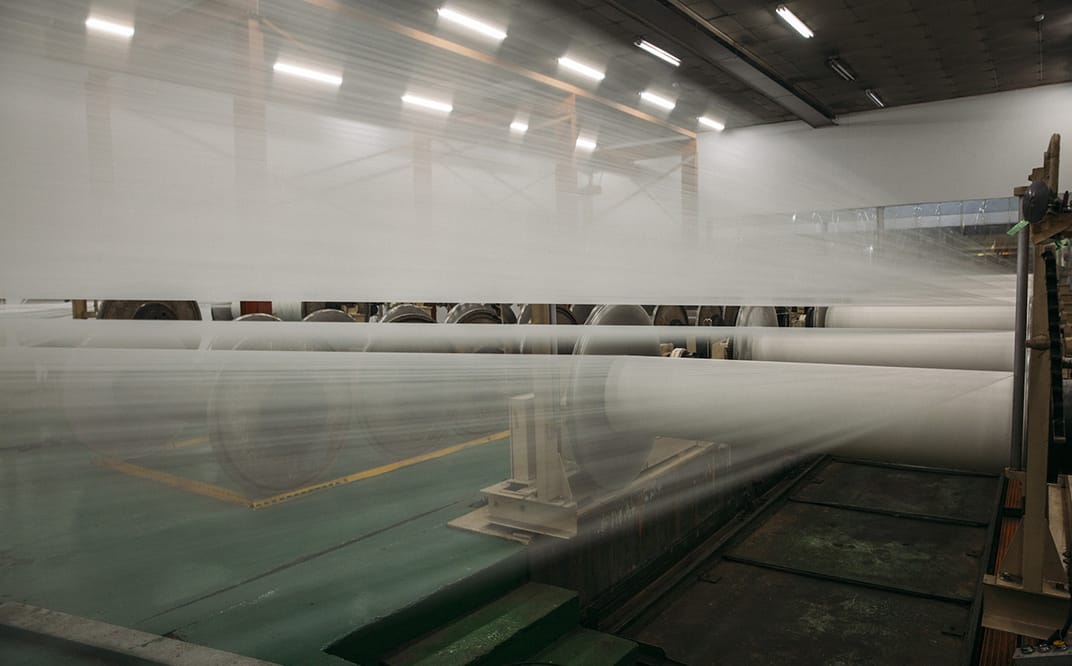

More than 1200 different spools simultaneously feed into a machine that winds each thread around a huge roller.

Spools in storage

You can really see each distinct thread coming off the spools. They feed into the machine.

Visually, all those parallel threads feeding from the spools into the machine is quite the incredible sight to see.

This is when the weaving actually begins!

Each fabric can be changed according to structure and aspect we want.

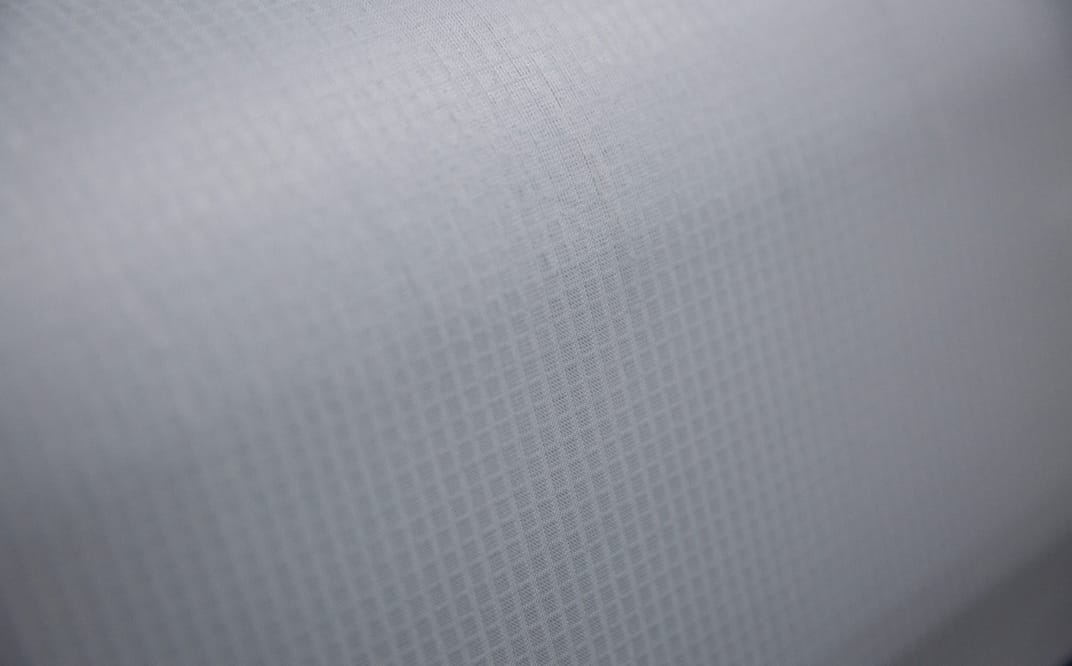

In simple terms, weaving is nothing more than interlacing threads.

The infernal cadence of the loom weaving and threads being pressed provides structure to the fabric.

The loom

The 2 levels of thread crisscross very quickly, and with each crossing, the machine places the thread in the other direction (the same direction as the jet of water that you see). Water makes the process smoother.

There you have it, raw untreated polyester fabric made from recycled plastic bottles!

See in episode 4: Dyeing fabric and laminating a waterproof-breathable membrane.